We are a British-owned company and were first established in the United Kingdom in 1923, then under the name Jessop & Baird. In 2004, we relocated the company to Hong Kong and consildated our European and African manufacturing operations in Zhongshan, China.

We are renowned as a category-leading garment innovator. We have a world-leading expertise in 3D-shaping and adhesive technology and today manufacture a wide range of apparel products for some of the worlds’ most respected and consumed brands.

In the course of our history, we have achieved multiple world-firsts and continue to use our technology and deep expertise to redefine what’s possible and create the garments of tomorrow.

Our innovative mentality and technology-driven expertise is what truly differentiates us. In the course of our history, we have consistently developed and manufactured products that have become marquee revenue lines for some of the world’s biggest and most forward-thinking brands.

Our technology is applicable to every sub-sector of the garment industry, but we have a particular experience in developing category-defining intimate and functional sportswear products for out clients.

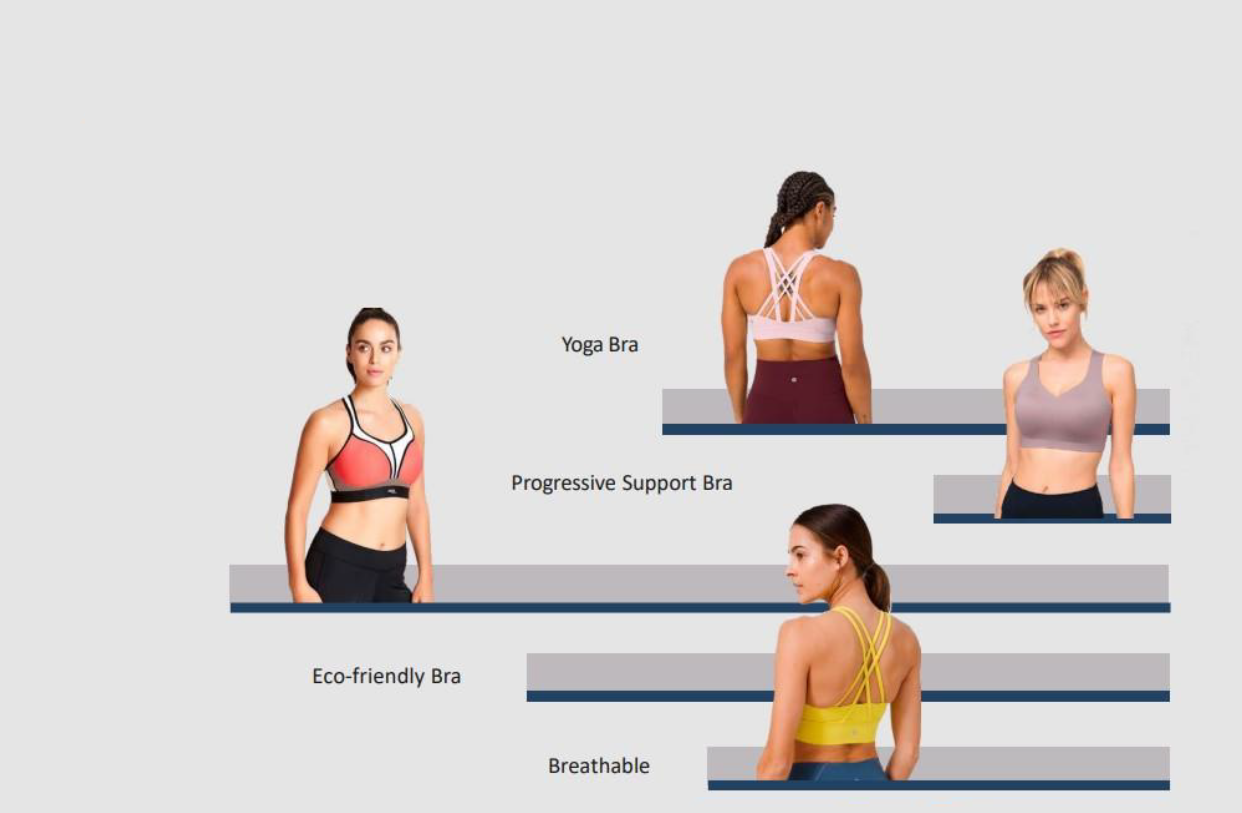

First in the world to develop bras using Simplex (knitted fabric)

First in the world to implement hot-melt lamination into bra cups (technology that was used in developing the 1994 Wonderbra)

First in the world to create a progressive support sports bra

Our team is continuously researching market trends to ensure we offer the most innovative products. Innovation is key to differentiation and we are constantly developing new technology to 3D moulding, gluing and fabrics for our clients.

We have an expert team of garment designers, pattern makers and technical engineers. They work together to develop the concept, implement new manufacturing methodologies and create the final garment.

Once the garment is approved, our highly experienced merchandising team will work closely with our production and technical teams to ensure we deliver our high-quality product on time and in-line with our sustainability targets.

One thing Seamless Solutions really takes to heart is the impact of its operations on the environment.

For this reason, we have been heavily investing in recycling technologies and implementing processes aimed at reducing waste and minimising our carbon footprint.

As of June 2022 Seamless Solution with be GRS certified and will be working with our customers to bring to market products that, in addition to being of the highest quality standards, also champion sustainable manufacturing.

We developed the world’s first progressive support bra for Lululemon and have since developed multiple new innovations that leverage the latest in performance fabrics and 3D moulding techniques.

We manufacture a full range of products, from everyday bras, and DD-G fit ranges to premium lingerie collections.

We have long-standing relationships with our suppliers and customers and never fail to deliver customised solutions, whilst also paying close attention to the fit, function and sustainability of all our products.

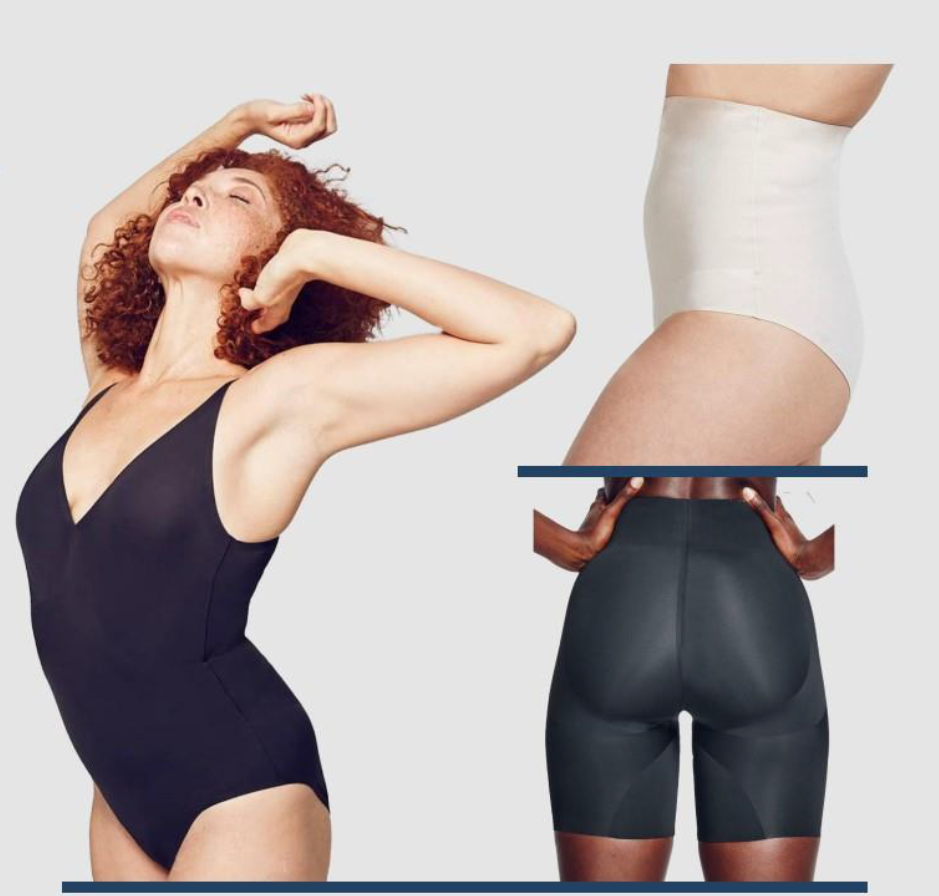

From bodysuit, to high waisted pants and contour shorts, we produce stylish shapewear that is breathable, seamless and delivers strong and even compression exactly where the customer wants it.

Whether the goal is lifting, smoothing or sculpting, we use our zonal support and form-fitting technology to help the consumer achieve a streamlined silhouette in total comfort.

1,000,000 pairs per month

Approx. 100,000 units per month

1,000,000 metrs per month

Centre in expansion phase

Underway to increase cup / garment capacity

Our wholly-owned factory subsidiary (Houze Science and Technology) is WRAP and OEKO-TEX certified.

Our in-house laboratory is accredited by the international certification agency Bureau Veritas.